LOTO services

Creation of a LOTO standard

Lockout Tagout can often be equated to constraints (waste of time, problems...), while it should be perceived, on the contrary, as a guarantee of safety. It is not unusual to see companies start this process and then stop along the way for lack of the implementation of a process at the same time simple, safe and most importantly operational.

Because each company is different (in terms of activity, organisation, operation, resources...), it is illusory to think that there is a unique solution applicable to everyone.

Based on this assesment, we offer to build, together, a LOTO process adapted to your activity, your organisation and your work environment and to provide you with the keys (tools, methods, tips) allowing you to properly prepare and coordinate the Lockout Tagout in order to gain in efficiency and to ban time consuming operations.

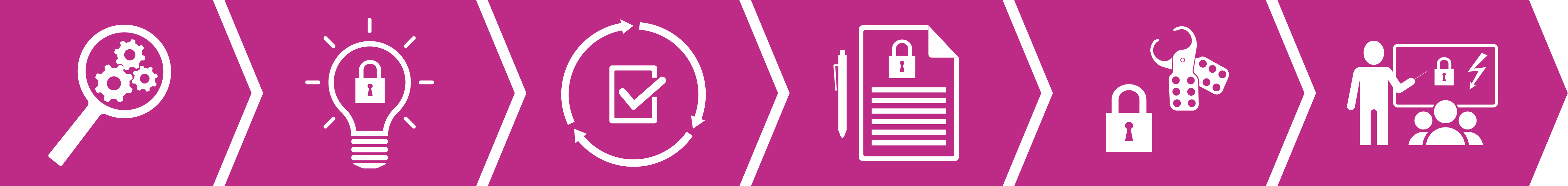

A global and operational approach

Our process is broken down into 6 main steps, from the definition of the LOTO process to the training of your employees, and include the supply of material resources.

DIAGNOSIS

The purpose of the diagnosis is to understand your organisation, your issues and your constraints in order to be able to offer you the most suitable solutions.

During this phase, we are going to meet you and to devote a significant time to exchange with all the personnel (supervisors and machine operators) directly and indirectly concerned by LOTO (managers, maintenance services, HSE service, HR/Training service...)

Goals of the exchanges:

-

Evaluate the organisation and the general operation method of the company (workforce, missions, skills of the different services, site requirements, frequency of the renovation and maintenance interventions, level of outsourcing...)

-

Analyse the organisation and the management of maintenance operations (management of long renovations, management of interventions, management of the operations carried out by the non process production, management of external companies, work authorisations, existing documents in relation with LOTO, management of trials, level of the existing technical documentation...)

-

Analyse your training process (content, method of assessment and transmission of skills, welcome of the new trainees...)

In addition, we will carry out a visit of your installations in order to become aware of the equipment used on the site (technical nature, vocabulary, environment) and evaluate the equipment (LOTO equipment at disposal on the site, resources of lockout to provide for carrying out LOTO, equipment for electrical safety...)

SOLUTIONS

At the end of the phase of diagnosis, we will provide a summary note on observations made in the field and we will offer you solutions to allow you to organise, manage and carry out Lockout Tagout in an efficient and safe way.

We can offer you relatively standard solutions (solutions that we have developed and that impose itself to our client over the years) and custom solutions that we specifically develop for you to respond to a specific need or problem.

OPERATIONAL TESTS

After having approved the organisational and material solutions together, we will offer you to put them to the test in the field by organising an operational testing phase within a production floor and a pilot site with your teams, in order to verify the suitability of the process for your organisation.

We write a process draft, create or revise the necessary documents to the implementation of the process (certification, LOTO order, tags...) and provide the material resources (padlocks, coordination panel...) to be able to carry out life-size tests.

Our teams stay available to assist you, either in the field or through written and oral exchanges, throughout the all testing phase.

Based on your feedback, we make modification or we improve the process until you are fully satisfied with the result.

LOTO PROCESS

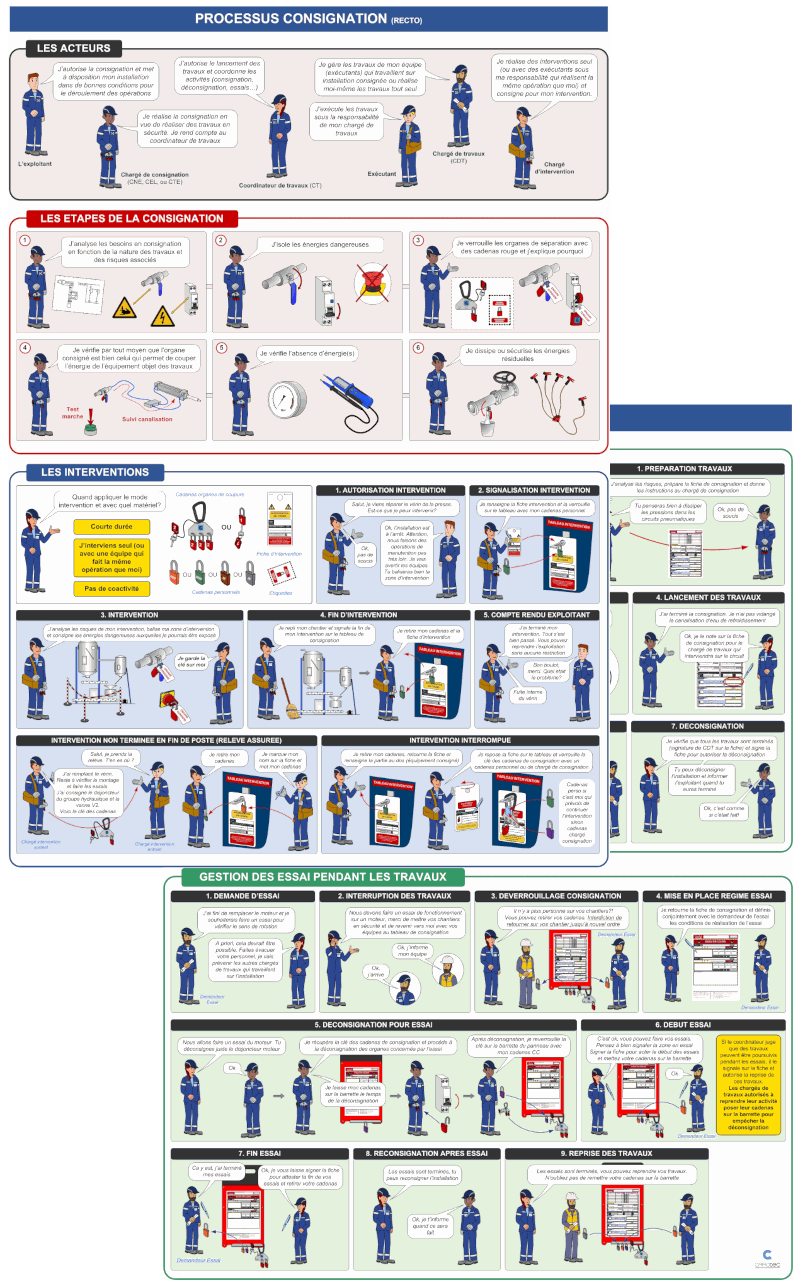

Once the solutions are approved and tested in the field, we write a general LOTO process (or control of dangerous energies). This aims to convey the implications of regulatory requirements, factory imperatives and the solutions adopted on an organisational, human, material and documentary level.

The procedure include all the necessary elements to the implementation of the process:

-

Glossary

-

Roles and responsibilities of relevant actors involved in the LOTO process

-

The different types of security (level 0,1, 2, 3 and 4)

-

Methodology of LOTO (fluidic, mechanical, electrical...)

-

Management and organisation of LOTO use cases (renovation, intervention, long-term LOTO…)

-

Special cases (loss of keys, omission of padlocks, LOTO test period, trial management...)

-

Skills and training of the personnel

The procedure is written so that it can be integrated into your quality/safety process with a will to be precise and as concise as possible, especially through the use of graphic resources (drawings, illustrated summary tables, processes described in the form of a comic...) allowing a quick understanding by everyone.

It takes into consideration the recommendations of the INRS and of the norm NF X 60-400 on the energies Lockout Tagout

RESOURCE

We provide all the necessary resource to the implementation of the general Lockout Tagout process and its implementation on the whole site (LOTO certification, management and coordination panels of standard or custom LOTO, padlocks, accessories, tags, tracking/marking equipment, electrical safety equipment...)

Thanks to the diagnosis carried out on your site, we are able to define the right quantity of equipment with the guarantee that it will be compatible with your equipment.

TRAINING

Finally, we provide the training of your personnel to ensure the proper application of your LOTO process and of the management of dangerous energies.

Different training sessions are offered according to the public

-

Awareness raising for managers, supervisors and production teams

-

Lockout Tagout training for the personnel carrying out the Lockout Tagout

In both cases, your process is entirely reviewed for a proper assimilation by the company personnel.

The trainings are carried out by employed trainers having significant experience in the field of Lockout Tagout and of the management of renovations in industry.

As part of our trainings, we attach particular importance to exchanges, collaboration between people, the acquisition of reflex gestures and know-how and the validation of acquired knowledge. To do this, we use modern techniques available on the market and we develop educational tools ourselves. We also emphasize the practical part with indoor exercises and on your installations.

Our references

They trust us: